Analysis Of Helical Shape Tube Type Heat Exchanger Using Cfd

Cfd Analysis Of Tube In Tube Helical Coil Heat Exchanger Pdf Heat In this work, cfd analysis for the performance analysis of counter flow type flow condition has been carried out. the various parameters such as temperature plots, velocity vectors, nusselt number, heat transfer rate from the wall of the tube has been calculated using ansys 13.0. Vimal kumar et al., numerically modeled tube in tube helical coil (tthc) heat exchanger for fluid flow and heat transfer characteristics at different fluid flow rates in inner as well as outer tube. new empirical correlation was developed for hydrodynamic and heat transfer prediction in the outer tube of tube in tube helical coil (tthc) heat.

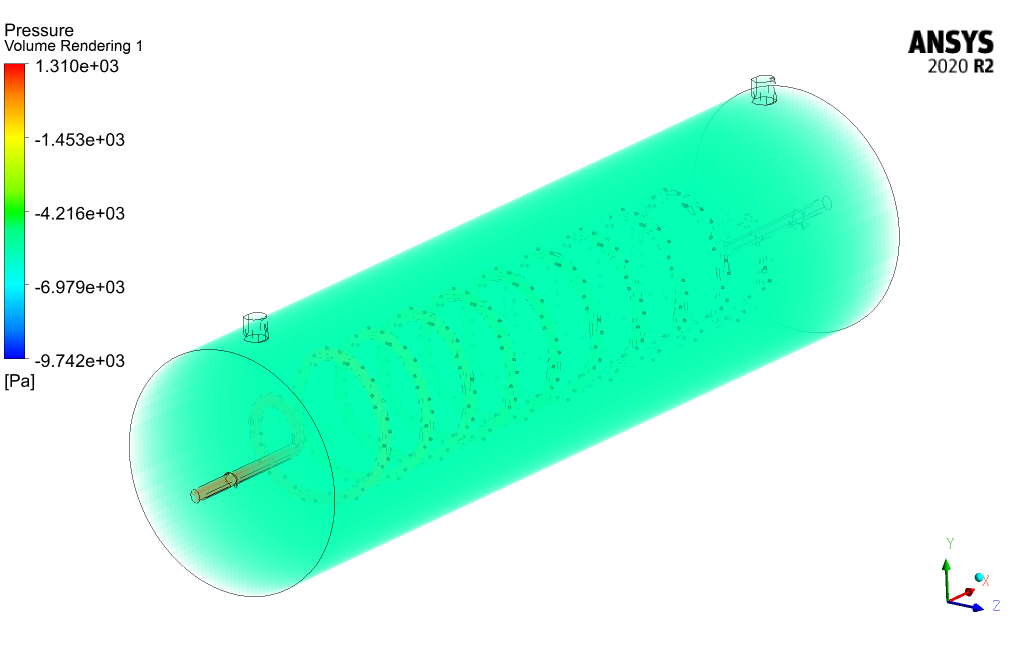

Shell And Helical Tube Heat Exchanger Cfd Simulation Ansys Fluent In the present study a tube in tube helically coiled heat exchanger has been modeled for fluid flow and an attempt has been made to analyze heat transfer characteristics for different fluid flow rates in the inner as well as outer tube. In this work, cfd analysis for the performance analysis of counter flow type flow condition has been carried out. the various parameters such as temperature plots, velocity vectors, nusselt number, heat transfer rate from the wall of the tube has been calculated using ansys 13.0. Helical tube heat exchanger provides certain advantage such as compact structure, larger heat transfer surface area and improved heat transfer capability. this thesis shows the deviation of nusselt number and friction factor for different curvature. In this work, cfd analysis for the performance analysis of counter flow type flow condition has been carried out. the various parameters such as temperature plots, velocity vectors, nusselt number, heat transfer rate from the wall of the tube has been calculated using ansys 13.0.

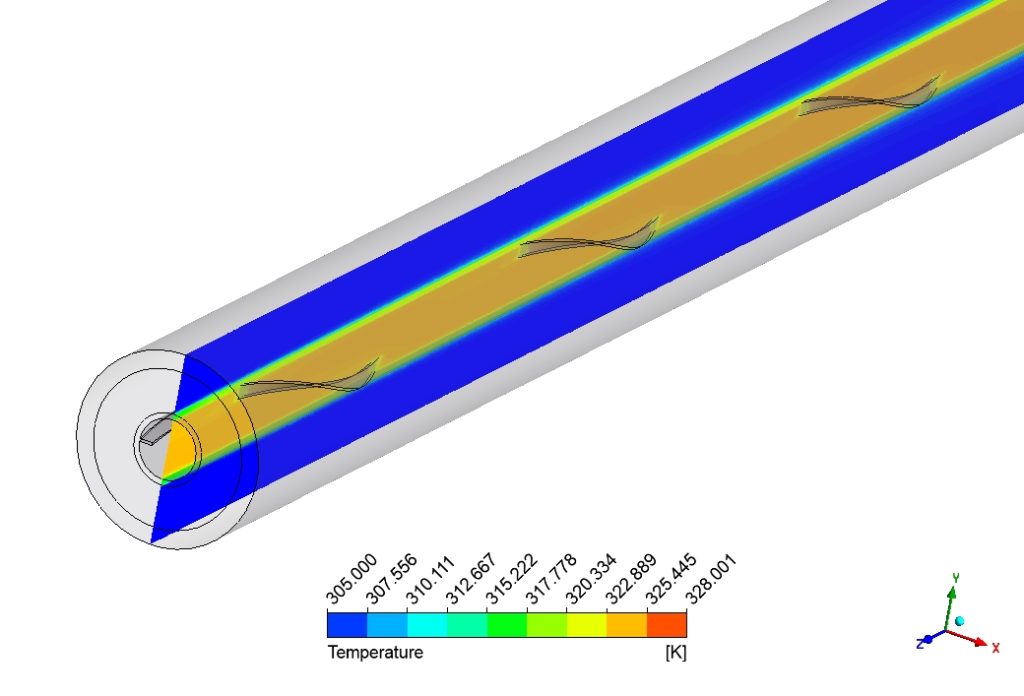

Shell And Helical Tube Heat Exchanger Cfd Simulation Ansys Fluent Helical tube heat exchanger provides certain advantage such as compact structure, larger heat transfer surface area and improved heat transfer capability. this thesis shows the deviation of nusselt number and friction factor for different curvature. In this work, cfd analysis for the performance analysis of counter flow type flow condition has been carried out. the various parameters such as temperature plots, velocity vectors, nusselt number, heat transfer rate from the wall of the tube has been calculated using ansys 13.0. A helically coil tube heat exchanger is generally applied in industrial applications due to its compact structure, larger heat transfer area and higher heat transfer capability, etc. the importance of compact heat exchangers (ches) has been recognized in aerospace, automobile,. This type of heat exchangers are classified into shell and tube, double pipe and spiral tube heat exchangers. literature review: nephron p., 2007, studied regarding the thermal performance and pressure drop of the spiral coil device with and while not helical crimped fins. Abstract this present work represents an experimental studies and cfd investigation for a counter flow tube in tube helical coil heat exchanger where hot water flows through the inner tube and cold water flows through the outer tube. an experimental setup is used for the estimation of the heat transfer characteristics. In the present study a tube in tube helically coiled heat exchanger has been modeled for fluid flow and heat transfer characteristics for different fluid flow rates in the inner as well.

Tube Heat Exchanger With Helical Groove Cfd Simulation Ansys Fluent A helically coil tube heat exchanger is generally applied in industrial applications due to its compact structure, larger heat transfer area and higher heat transfer capability, etc. the importance of compact heat exchangers (ches) has been recognized in aerospace, automobile,. This type of heat exchangers are classified into shell and tube, double pipe and spiral tube heat exchangers. literature review: nephron p., 2007, studied regarding the thermal performance and pressure drop of the spiral coil device with and while not helical crimped fins. Abstract this present work represents an experimental studies and cfd investigation for a counter flow tube in tube helical coil heat exchanger where hot water flows through the inner tube and cold water flows through the outer tube. an experimental setup is used for the estimation of the heat transfer characteristics. In the present study a tube in tube helically coiled heat exchanger has been modeled for fluid flow and heat transfer characteristics for different fluid flow rates in the inner as well.

Ansys Tutorial Cfd Analysis Of Double Pipe Helical Heat Exchanger Images Abstract this present work represents an experimental studies and cfd investigation for a counter flow tube in tube helical coil heat exchanger where hot water flows through the inner tube and cold water flows through the outer tube. an experimental setup is used for the estimation of the heat transfer characteristics. In the present study a tube in tube helically coiled heat exchanger has been modeled for fluid flow and heat transfer characteristics for different fluid flow rates in the inner as well.

Comments are closed.