Capturing Data From Ded Directed Energy Deposition 3d Printing

Directed Energy Deposition Ded Metal 3d Printing The Ultimate Guide Additive manufacturing has gained significant attention for its potential to create innovative, lightweight, and strong products. however, it presents unique challenges, particularly uncertainties in how input parameters affect the final product, including material performance variations and geometrical defects [1], [2], [3], [4].this study focuses on laser powder directed energy deposition. 3d printing is often called a digital manufacturing technology for the way that the process is driven by data files; without digital instructions, a 3d printer cannot print. but equally.

Introduction To Ded In Additive Manufacturing Explore Directed Energy It explores the critical process mechanisms that can lead to defect formation in the manufactured parts, offering in depth insights into the factors that influence these outcomes. additionally, the unique mechanisms of defect formation inherent to directed energy deposition are examined in detail. Directed energy deposition. it explores the critical process mechanisms that can lead to defect formation in the manufactured parts, offering in depth insights into. Rodriguez et al. examined the effects of deposition parameters, including the arc current, the wire feed rate, the arc voltage, the travel speed, the arc length, the deposition rate, and the deposition path, on bead formations, temperature histories during deposition and tensile properties for waam processes based on cmt and toptig. Among metal additive manufacturing (mam) technologies, directed energy deposition (ded) enables large scale printing. wire ded has shown significant growth with various processes using different energy sources, yet a comprehensive comparison is lacking. this study investigates three wire fed ded technologies: laser metal deposition (lmd), plasma transferred arc (pta), and gas metal arc (gma.

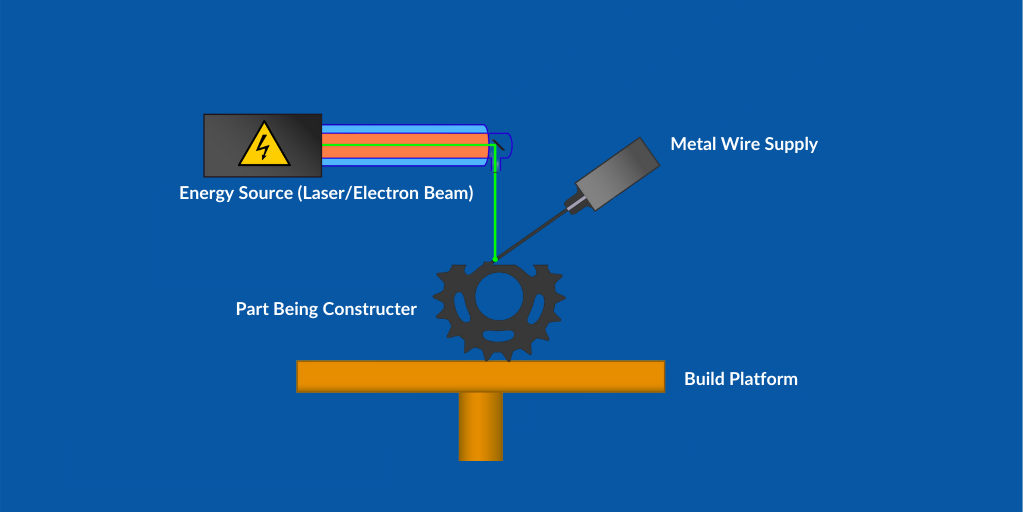

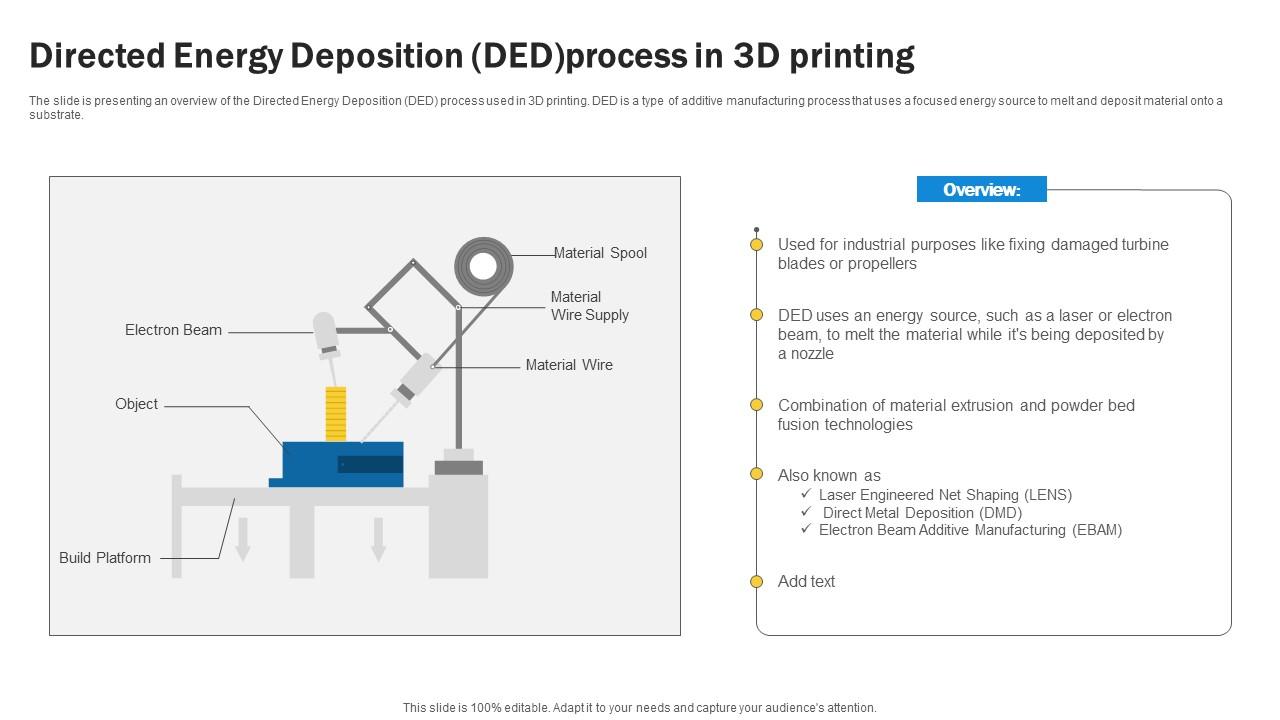

3d Printing Directed Energy Deposition Ded Process In 3d Printing Ppt Rodriguez et al. examined the effects of deposition parameters, including the arc current, the wire feed rate, the arc voltage, the travel speed, the arc length, the deposition rate, and the deposition path, on bead formations, temperature histories during deposition and tensile properties for waam processes based on cmt and toptig. Among metal additive manufacturing (mam) technologies, directed energy deposition (ded) enables large scale printing. wire ded has shown significant growth with various processes using different energy sources, yet a comprehensive comparison is lacking. this study investigates three wire fed ded technologies: laser metal deposition (lmd), plasma transferred arc (pta), and gas metal arc (gma. This work proposes a novel multimodal deep learning approach for temperature prediction with uncertainty quantification in directed energy deposition (ded) process. the proposed methodology implements multimodal data fusion, combining reproduced grayscale images of deposition strategy with numerical process variables, including process. Direct energy disposition (ded) is one of the additive manufacturing methods. additive manufacturing (am) may seem a little bit unfamiliar to you. it is also called 3d printing, rapid prototyping (rp), layer manufacturing, etc. the main core of addictive manufacturing is using 3d model data to join materials layer by layer. Directed energy deposition (ded) 3d printing is revolutionizing metal additive manufacturing. its flexibility, efficiency, and precision make it a powerful tool for industries ranging from aerospace to medicine. Electron beam directed energy deposition (eb ded) is an am process in which raw material in the form of wire is deposited layer by layer by using an electron beam as the heat source. ebam ® (sciaky inc, usa), webam (pro beam, germany), eboadd (steigerwald, germany), etc., are some of the popular commercial systems using filament based eb gun.

Learn 3d Printing Directed Energy Deposition Ded Eshoptrip This work proposes a novel multimodal deep learning approach for temperature prediction with uncertainty quantification in directed energy deposition (ded) process. the proposed methodology implements multimodal data fusion, combining reproduced grayscale images of deposition strategy with numerical process variables, including process. Direct energy disposition (ded) is one of the additive manufacturing methods. additive manufacturing (am) may seem a little bit unfamiliar to you. it is also called 3d printing, rapid prototyping (rp), layer manufacturing, etc. the main core of addictive manufacturing is using 3d model data to join materials layer by layer. Directed energy deposition (ded) 3d printing is revolutionizing metal additive manufacturing. its flexibility, efficiency, and precision make it a powerful tool for industries ranging from aerospace to medicine. Electron beam directed energy deposition (eb ded) is an am process in which raw material in the form of wire is deposited layer by layer by using an electron beam as the heat source. ebam ® (sciaky inc, usa), webam (pro beam, germany), eboadd (steigerwald, germany), etc., are some of the popular commercial systems using filament based eb gun.

3d Printing Working Of Directed Energy Deposition Ded Process Ppt Slide Directed energy deposition (ded) 3d printing is revolutionizing metal additive manufacturing. its flexibility, efficiency, and precision make it a powerful tool for industries ranging from aerospace to medicine. Electron beam directed energy deposition (eb ded) is an am process in which raw material in the form of wire is deposited layer by layer by using an electron beam as the heat source. ebam ® (sciaky inc, usa), webam (pro beam, germany), eboadd (steigerwald, germany), etc., are some of the popular commercial systems using filament based eb gun.

The Complete Guide To Directed Energy Deposition Ded In 3d Printing

Comments are closed.