Cfd Simulation Of A Heat Recovery Steam Generator Hrsg

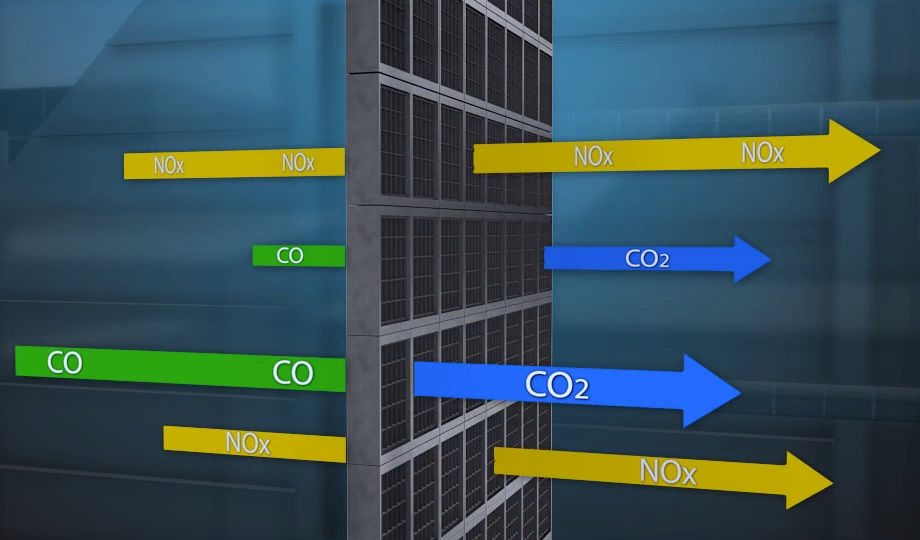

Heat Recovery Steam Generator Hrsg Chemical Engineering Pdf Cfd engineering uk coupled fluid flow and heat transfer simulation. ive been planning to come up with this application for some time now because its a very nice example of how a machine with. A coupled cfd oxidation model to study high temperature oxidation in superheaters (sh) and reheaters (rh) of hrsg is presented.

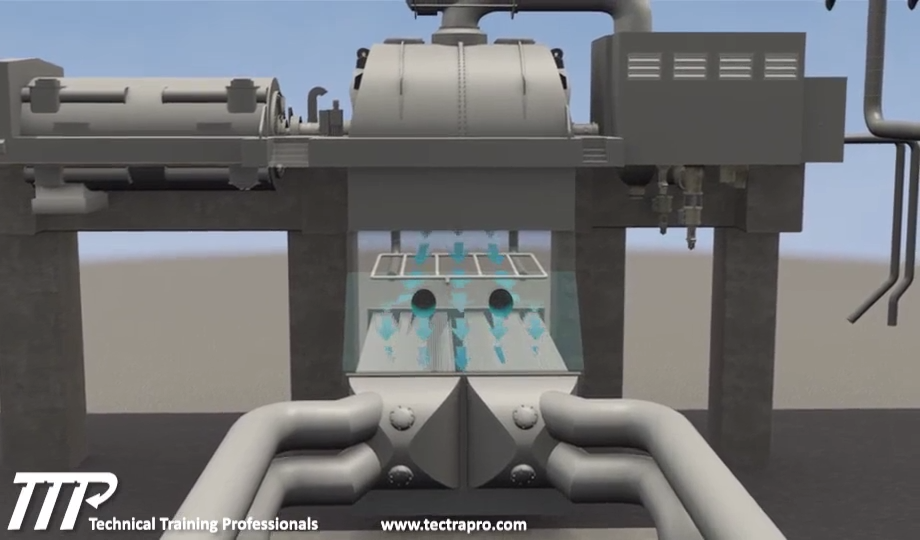

Heat Recovery Steam Generator Hrsg Fundamentals Technical Training This article presents the transient cfd modeling results of residual fuel concentration in a typical hrsg configuration during a gas turbine combined cycle startup failure process. This thesis focuses on how cfd analysis can be used to assess the impact of the gas side flow on the hrsg performance and identify design modifications to improve the performance. an effort is also made to explore the software capabilities to make the simulation an efficient and accurate. An hrsg is a facility for recovering energy from hot exhaust gases from a gas turbine. the flow at the inlet has a rotational component as it passes through the turbine, and to simulate this, a profile of the inlet velocity is given to the boundary conditions. This article presents an application of genetic algorithm (ga) based fuzzy clustering approach for developing accurate non linear models for a heat recovery steam generator (hrsg).

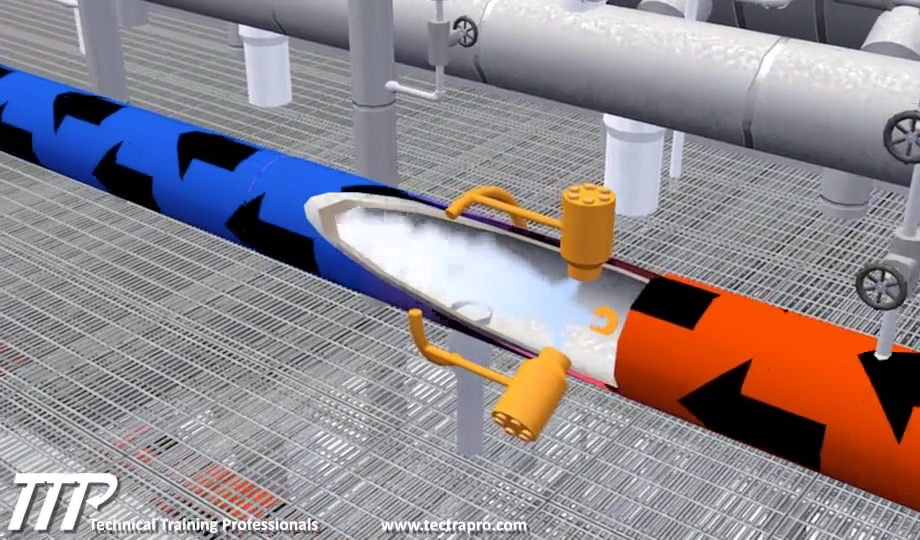

Heat Recovery Steam Generator Hrsg Fundamentals Technical Training An hrsg is a facility for recovering energy from hot exhaust gases from a gas turbine. the flow at the inlet has a rotational component as it passes through the turbine, and to simulate this, a profile of the inlet velocity is given to the boundary conditions. This article presents an application of genetic algorithm (ga) based fuzzy clustering approach for developing accurate non linear models for a heat recovery steam generator (hrsg). A steady state cfd simulation was conducted to evaluate the aerodynamic behavior within the hrsg system. the analysis focused on identifying pressure loss regions and recirculation zones, visualizing velocity distribution and mixing, and determining the minimum flow velocity required to keep the damper flap open under operating conditions. Once the closed loop simulations were demonstrated, a full hrsg model was created. this model was compiled and downloaded to siemens plc hardware and run without active controls at steady state conditions. the simulation results demonstrated numerical stability when run at real time. The combined cycle power plant consists of topping cycle, bottoming cycles and heat recovery steam generators (hrsgs) as the integral systems. the main focus of this work is to predict and analyse fluid flow behaviour in hrsg. In the present work, a full scale cfd model based on the eulerian lagrangian scheme is implemented to simulation flue gas turbulent flow and heat transfer as well as the particle transport in.

Heat Recovery Steam Generator Hrsg Fundamentals Technical Training A steady state cfd simulation was conducted to evaluate the aerodynamic behavior within the hrsg system. the analysis focused on identifying pressure loss regions and recirculation zones, visualizing velocity distribution and mixing, and determining the minimum flow velocity required to keep the damper flap open under operating conditions. Once the closed loop simulations were demonstrated, a full hrsg model was created. this model was compiled and downloaded to siemens plc hardware and run without active controls at steady state conditions. the simulation results demonstrated numerical stability when run at real time. The combined cycle power plant consists of topping cycle, bottoming cycles and heat recovery steam generators (hrsgs) as the integral systems. the main focus of this work is to predict and analyse fluid flow behaviour in hrsg. In the present work, a full scale cfd model based on the eulerian lagrangian scheme is implemented to simulation flue gas turbulent flow and heat transfer as well as the particle transport in.

Comments are closed.