Directed Energy Deposition Ded Metal 3d Printing The Ultimate Guide

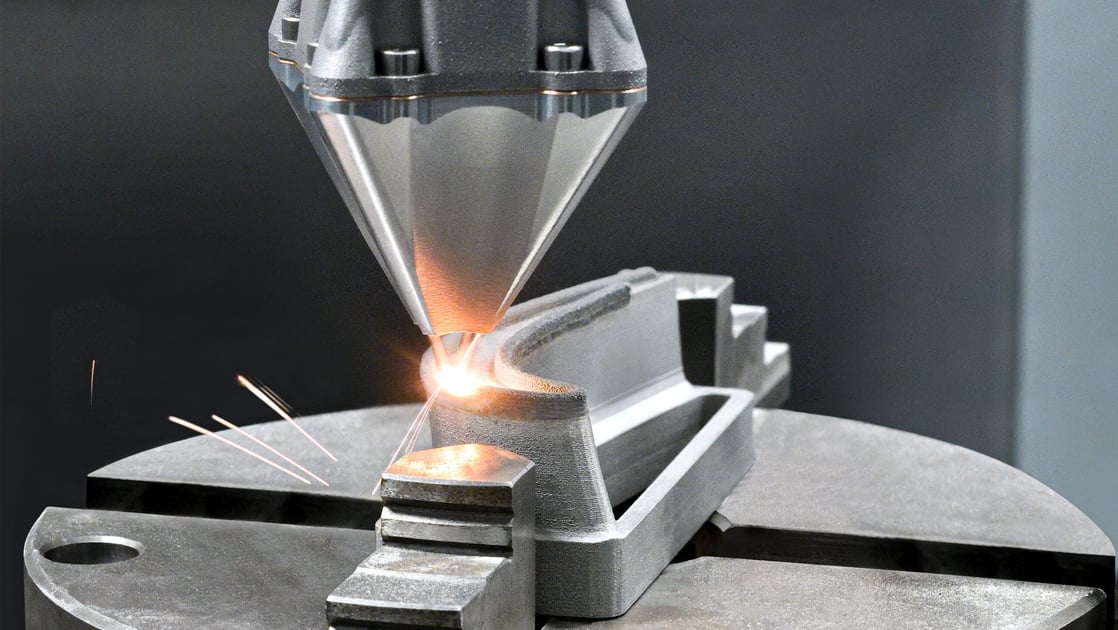

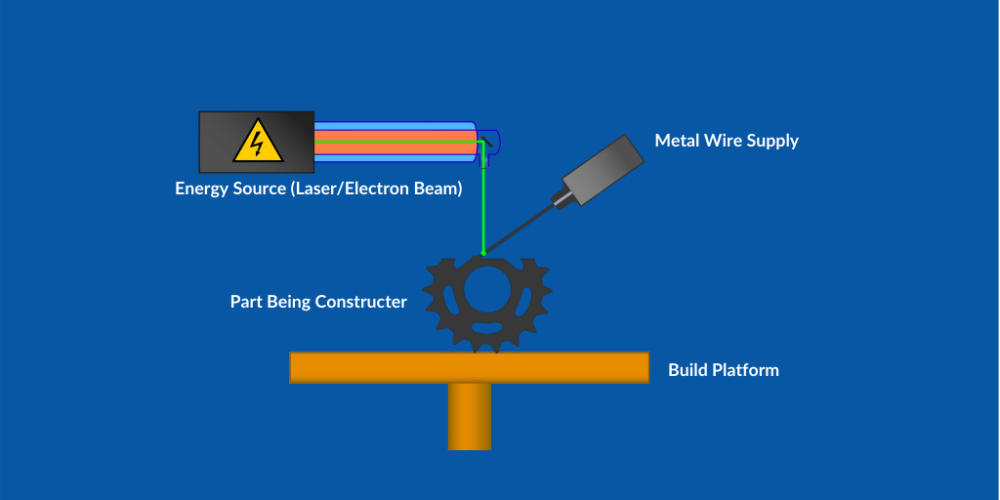

Directed Energy Deposition Ded 3d Printing Metal Powderä Truer Would you like to make a deposit? this 3d printing process melts metal powder or wire as it's deposited to repair or manufacture a wide range of parts. Directed energy deposition (ded) — sometimes just direct energy deposition — is a metal 3d printing technology offering key advantages in larger metal part creation. similar to other metal 3d printing methods, ded builds parts by sintering metal in layers to form a three dimensional structure.

Directed Energy Deposition Ded Metal 3d Printing The Ultimate Guide In the always changing world of metal 3d printing, direct energy deposition (ded) printers have become a game changing technology. this ultimate guide seeks to give a thorough understanding of ded printers, their unique capabilities, applications and advantages over traditional manufacturing methods. Similarly to some powder bed fusion (pbf) technologies (such as lpbf or ebm), directed energy deposition uses a focused energy source, such as a laser or electron beam to melt the material. however, the material is melted at the same time as it’s deposited by a nozzle. Here is a complete guide to ded 3d printing technologies, the materials suitable for ded, different ded processes, ded and applications and where wire arc additive manufacturing fits into the picture. We have come up with this article to help you get what ded technology means, and also listed some of the most fascinating facts about it.

Metal 3d Printing Processes Directed Energy Deposition Ded 3deo Here is a complete guide to ded 3d printing technologies, the materials suitable for ded, different ded processes, ded and applications and where wire arc additive manufacturing fits into the picture. We have come up with this article to help you get what ded technology means, and also listed some of the most fascinating facts about it. “within one of formalloy’s powder or wire fed ded printers, sensors are monitoring the meltpool size, the laser power, even the temperature of the optical glass,” writes stephanie hendrixson, editor in chief of additive manufacturing. Simplified workflow metal additive manufacturing (am) follows a structured workflow, but the details vary depending on the specific technology used—powder bed fusion (pbf), binder jetting, directed energy deposition (ded), or bound powder extrusion (bpe). 1. digital design and modelling engineers begin with a 3d cad model, exported in formats such as stl or 3mf to represent surface geometry. This comprehensive guide delves into every aspect of ded, from its basic principles to the intricate details of metal powders used in the process. let’s embark on this journey to understand the fascinating world of ded. Direct energy deposition (ded) – 3d printing for manufacturing and repairing metal. read about advantages, applications and future of ded here.

Direct Energy Deposition Saves Time Lowers Costs 3d Metal Printing “within one of formalloy’s powder or wire fed ded printers, sensors are monitoring the meltpool size, the laser power, even the temperature of the optical glass,” writes stephanie hendrixson, editor in chief of additive manufacturing. Simplified workflow metal additive manufacturing (am) follows a structured workflow, but the details vary depending on the specific technology used—powder bed fusion (pbf), binder jetting, directed energy deposition (ded), or bound powder extrusion (bpe). 1. digital design and modelling engineers begin with a 3d cad model, exported in formats such as stl or 3mf to represent surface geometry. This comprehensive guide delves into every aspect of ded, from its basic principles to the intricate details of metal powders used in the process. let’s embark on this journey to understand the fascinating world of ded. Direct energy deposition (ded) – 3d printing for manufacturing and repairing metal. read about advantages, applications and future of ded here.

Introduction To Ded In Additive Manufacturing Explore Directed Energy This comprehensive guide delves into every aspect of ded, from its basic principles to the intricate details of metal powders used in the process. let’s embark on this journey to understand the fascinating world of ded. Direct energy deposition (ded) – 3d printing for manufacturing and repairing metal. read about advantages, applications and future of ded here.

Comments are closed.