Directed Energy Deposition English Version

Directed Energy Deposition Synergy Additive Manufacturing This video course focuses on the 3d printing technology directed energy deposition or ded.00:00 introduction02:03 what is directed energy deposition?07:48. Directed energy deposition (ded) forms 3d objects by melting material as it is deposited using focused thermal energy, such as a laser, electron beam, or plasma arc. ded is one of the seven categories of additive manufacturing processes, which uses 3d data to build objects layer by layer instead of using subtractive manufacturing technologies.

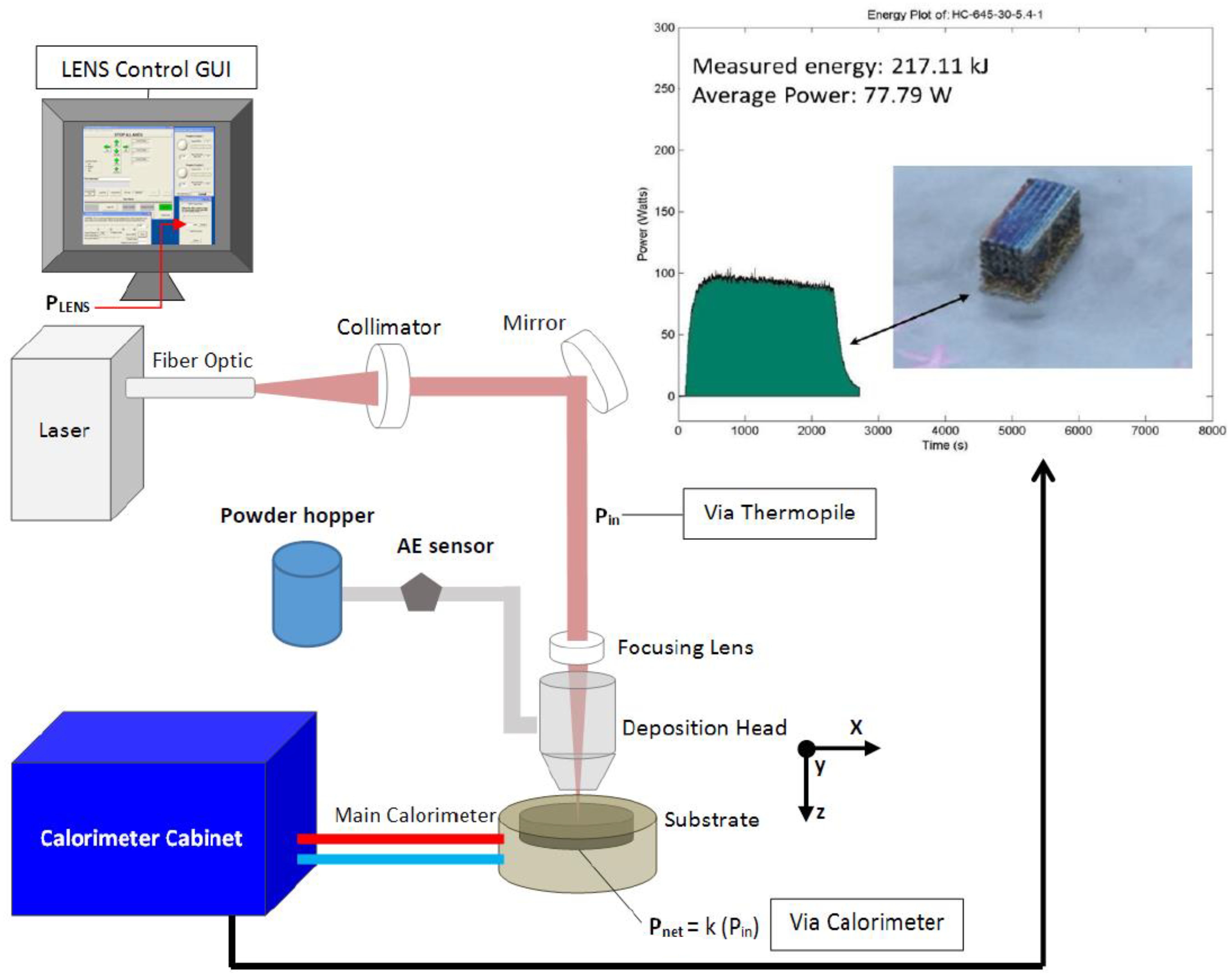

Directed Energy Deposition Directed energy deposition (ded) is a branch of additive manufacturing (am) processes in which a feedstock material in the form of powder or wire is delivered to a substrate on which an energy source such as laser beam, electron beam, or plasma electric arc is simultaneously focused, thus forming a small melt pool and continuously depositing. Directed energy deposition (ded) is a branch of additive manufacturing (am) processes in which a feedstock material in the form of powder or wire is delivered to a substrate on which an energy source such as laser beam, electron beam, or plasma electric arc is simultaneously focused, thus forming a small melt pool and continuously depositing. Metal additive manufacturing technologies, such as powder bed fusion process, directed energy deposition (ded) process, sheet lamination process, etc., are one of promising flexible manufacturing technologies due to direct fabrication characteristics of a metallic freeform with a three dimensional shape from computer aided design data. 1. introduction directed energy deposition (ded) process is an additive manufacturing (am) process, in which a focused thermal energy source fuses aterial, in general metallic powder, or wire, by melting them during layer by layer deposition [1].

Directed Energy Deposition Metal additive manufacturing technologies, such as powder bed fusion process, directed energy deposition (ded) process, sheet lamination process, etc., are one of promising flexible manufacturing technologies due to direct fabrication characteristics of a metallic freeform with a three dimensional shape from computer aided design data. 1. introduction directed energy deposition (ded) process is an additive manufacturing (am) process, in which a focused thermal energy source fuses aterial, in general metallic powder, or wire, by melting them during layer by layer deposition [1]. What is ded? direct energy deposition (ded) is a family of additive manufacturing technologies that uses a directed heat source to fuse a feedstock material. ded of metals allows additive manufacturing of large scale metallic components at a much higher deposition rate compared to other am technologies, such as powder bed fusion (pbf). Directed energy deposition (ded) builds up material layer by layer. a nozzle deposits and melts material onto a target with a directed beam of energy, such as a laser or an electron beam. the material cools and forms a solid part. •uses a laser energy source with a off axis wire feed and local purge •100% efficiency in material usage •high deposition rates, but balances low heat input. Directed energy deposition (ded) is an additive manufacturing process that melts a feedstock material during deposition with a focused thermal energy source, which is typically a laser, electron beam, gas metal arc, or a plasma arc . ded differentiates itself from the other categories of additive manufacturing processes in that the process is.

Directed Energy Deposition What is ded? direct energy deposition (ded) is a family of additive manufacturing technologies that uses a directed heat source to fuse a feedstock material. ded of metals allows additive manufacturing of large scale metallic components at a much higher deposition rate compared to other am technologies, such as powder bed fusion (pbf). Directed energy deposition (ded) builds up material layer by layer. a nozzle deposits and melts material onto a target with a directed beam of energy, such as a laser or an electron beam. the material cools and forms a solid part. •uses a laser energy source with a off axis wire feed and local purge •100% efficiency in material usage •high deposition rates, but balances low heat input. Directed energy deposition (ded) is an additive manufacturing process that melts a feedstock material during deposition with a focused thermal energy source, which is typically a laser, electron beam, gas metal arc, or a plasma arc . ded differentiates itself from the other categories of additive manufacturing processes in that the process is.

Directed Energy Deposition •uses a laser energy source with a off axis wire feed and local purge •100% efficiency in material usage •high deposition rates, but balances low heat input. Directed energy deposition (ded) is an additive manufacturing process that melts a feedstock material during deposition with a focused thermal energy source, which is typically a laser, electron beam, gas metal arc, or a plasma arc . ded differentiates itself from the other categories of additive manufacturing processes in that the process is.

Directed Energy Deposition

Comments are closed.