Safety Procedures For Using Abrasive Wheels Pdf

Safety Procedures For Using Abrasive Wheels Pdf (a) hazards and risks arising from the use of abrasive wheels and the precautions to be observed; (b) methods of marking abrasive wheels with their type, size and maximum operating speed; (c) how to store handle and transport abrasive wheels; (d) how to inspect and test abrasive wheels for damage;. Abrasive wheels are marked to identify their characteristics. persons responsible for wheel mounting should be able to recognise the specifications marked on the wheel (see fig. 4). all mountings shall only be done by competent persons appointed in writing by the proprietors.

Abrasive Wheels Safety From Aspli Safety What safety procedures should you follow when using bench and pedestal grinders? an operator must be fully trained and instructed in the safe use, care, and protection from abrasive wheels before use. fasten the pedestal and bench grinders on a solid surface securely. ensure all the guards are in place and secure before using a grinder. Best practice in health and safety management begins with a thorough risk assessment. the first priority is to identify hazards, e.g. the equipment and activities with the potential to cause harm, the nature of the hazard, the extent of exposure, and employees that might be affected. That’s what this program is all about: how to operate an abrasive grinder safely without incident. topics include abrasive wheel hazards, ppe, grinder inspection, work rests and tongue guards, dangers of operating in overspeed conditions, grinding wheel inspection, fire prevention and preventing slips, trips and falls. The safe use, care and protection of abrasive wheels and the machines for which they are designed. included in this standard are the requirements for safety guards, flanges, chucks and proper storage, handling and mounting techniques. exclusions from this standard are natural sand stone, pulpstone and coated abrasive products.

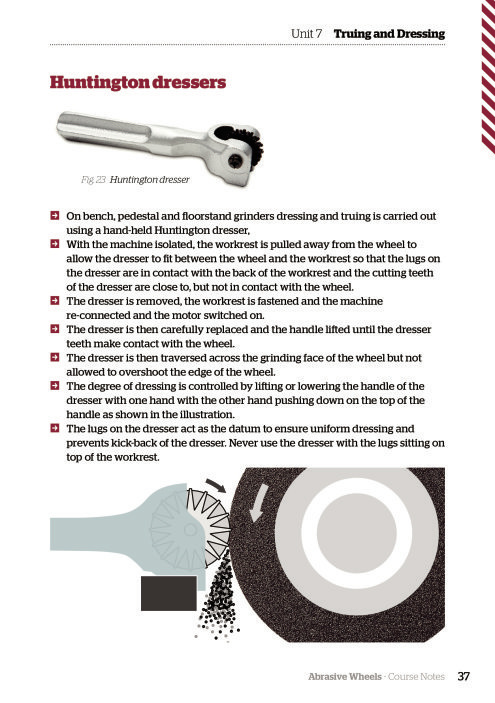

Abrasive Wheels Safety Guide Book That’s what this program is all about: how to operate an abrasive grinder safely without incident. topics include abrasive wheel hazards, ppe, grinder inspection, work rests and tongue guards, dangers of operating in overspeed conditions, grinding wheel inspection, fire prevention and preventing slips, trips and falls. The safe use, care and protection of abrasive wheels and the machines for which they are designed. included in this standard are the requirements for safety guards, flanges, chucks and proper storage, handling and mounting techniques. exclusions from this standard are natural sand stone, pulpstone and coated abrasive products. Follow best practices and manufacturer’s guidelines! bring questions and injuries to your supervisor! direct additional questions to ehs. if working outside your designated area, you may need a hot work permit. contact [email protected]. in an emergency, call 911 and uopd (541 346 2919) for immediate assistance!. To ensure that grinding wheels are safely used in your workplace, know the hazards and how to control them. breathing in dusts can cause respiratory problems. contact with lubricating oils and metallic dusts can irritate the skin. if compressed air (used with air powered grinders) enters the bloodstream, it can be deadly. In addition to looking at essential training needs, the guide also focuses on details such as: wheel characteristics; safety in grinding machine operations; wheel mounting procedures and. Abrasive wheels? what safety precautions should be followed when using abrasive wheels? select the right wheel for the job. a wheel is dangerous when used for work for which it was not designed. booklets from wheel and machine manufacturers provide technical information on wheel selection and proper use. use only wheels marked with the wheel.

Abrasive Wheels Safety Guide Book Follow best practices and manufacturer’s guidelines! bring questions and injuries to your supervisor! direct additional questions to ehs. if working outside your designated area, you may need a hot work permit. contact [email protected]. in an emergency, call 911 and uopd (541 346 2919) for immediate assistance!. To ensure that grinding wheels are safely used in your workplace, know the hazards and how to control them. breathing in dusts can cause respiratory problems. contact with lubricating oils and metallic dusts can irritate the skin. if compressed air (used with air powered grinders) enters the bloodstream, it can be deadly. In addition to looking at essential training needs, the guide also focuses on details such as: wheel characteristics; safety in grinding machine operations; wheel mounting procedures and. Abrasive wheels? what safety precautions should be followed when using abrasive wheels? select the right wheel for the job. a wheel is dangerous when used for work for which it was not designed. booklets from wheel and machine manufacturers provide technical information on wheel selection and proper use. use only wheels marked with the wheel.

Abrasive Wheels Safety Guide Book In addition to looking at essential training needs, the guide also focuses on details such as: wheel characteristics; safety in grinding machine operations; wheel mounting procedures and. Abrasive wheels? what safety precautions should be followed when using abrasive wheels? select the right wheel for the job. a wheel is dangerous when used for work for which it was not designed. booklets from wheel and machine manufacturers provide technical information on wheel selection and proper use. use only wheels marked with the wheel.

Comments are closed.