Smart Investments Can Accelerate Your Smart Factory Transformation

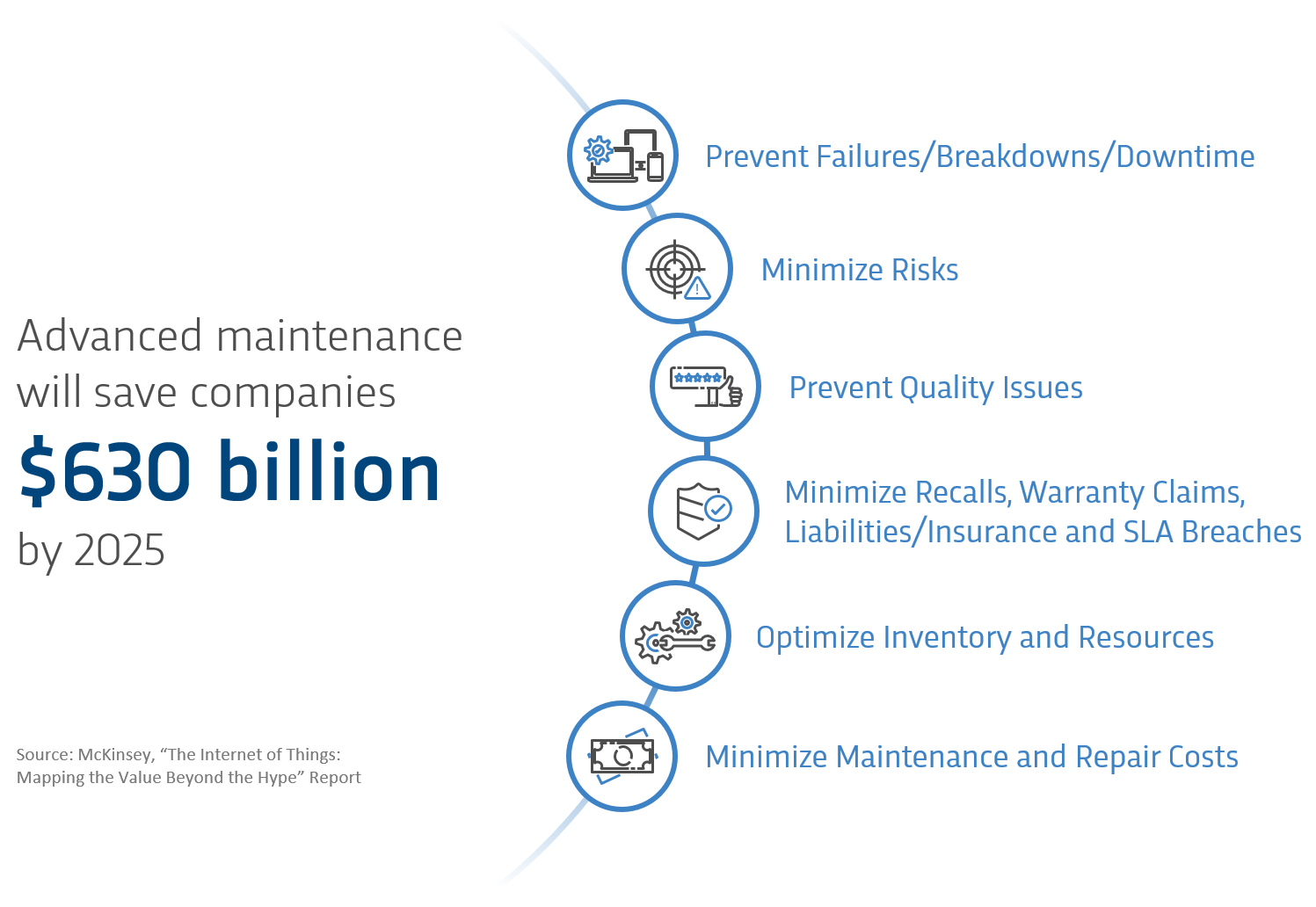

Smart Investments Can Accelerate Your Smart Factory Transformation Manufacturers are experiencing a time of tremendous change, especially in the operations landscape, as the industry transforms from a production line comprised of analog tools and machines to a fully connected smart factory. Forward looking manufacturers are investing in ai, iot, robotics, and other advanced technologies to enhance customer value, operations, and sustainability, while also concurrently pursuing "smart" practices in a multitude of other strategic areas from operations to customer value to sustainability.

Smart Investments Can Accelerate Your Smart Factory Transformation Smart factory applications are transforming the future of factories. see how smart manufacturing can help accelerate organizations to a smarter operating model. Transformative smart factory projects can be capital intensive and myopic in vision and execution. manufacturing cios must reinvent how they fund advanced technologies that favor operating expenses and take an enterprisewide approach to drive adoption at the speed and agility these projects demand. Pwc’s smart factory tech enabled services combine digital, modern and foundational capabilities, through our ‘value first, outcomes back’ approach, to drive manufacturing to become more flexible, more efficient and less prone to interruptions. But transformation can be complex and time consuming. here, industry experts discuss how manufacturers are ensuring the success and effectiveness of adopting smart production processes.

Unblocking The Digital Transformation Of Your Smart Factory Syntax Pwc’s smart factory tech enabled services combine digital, modern and foundational capabilities, through our ‘value first, outcomes back’ approach, to drive manufacturing to become more flexible, more efficient and less prone to interruptions. But transformation can be complex and time consuming. here, industry experts discuss how manufacturers are ensuring the success and effectiveness of adopting smart production processes. Learn how supply chain and manufacturing operations leaders balance technology innovation and workforce development when cultivating future factory workforces. As capgemini’s report reveals, half of manufacturing businesses in the uk, france, germany and the us are ready to implement a smart factory initiative—with the efficiency and productivity benefits they offer—if they aren’t already. Organizations have already made one third of their factories smart, with a plan to transform an additional 40% over the next five years. learn how frontrunners are scaling to success. By analyzing concrete examples from industry leaders, this guide illuminates proven strategies for successful smart factory deployment. one of the most significant hurdles in transitioning to a smart factory is integrating new technologies with existing legacy systems.

Comments are closed.