The Complete Guide To Directed Energy Deposition Ded In 3d Printing

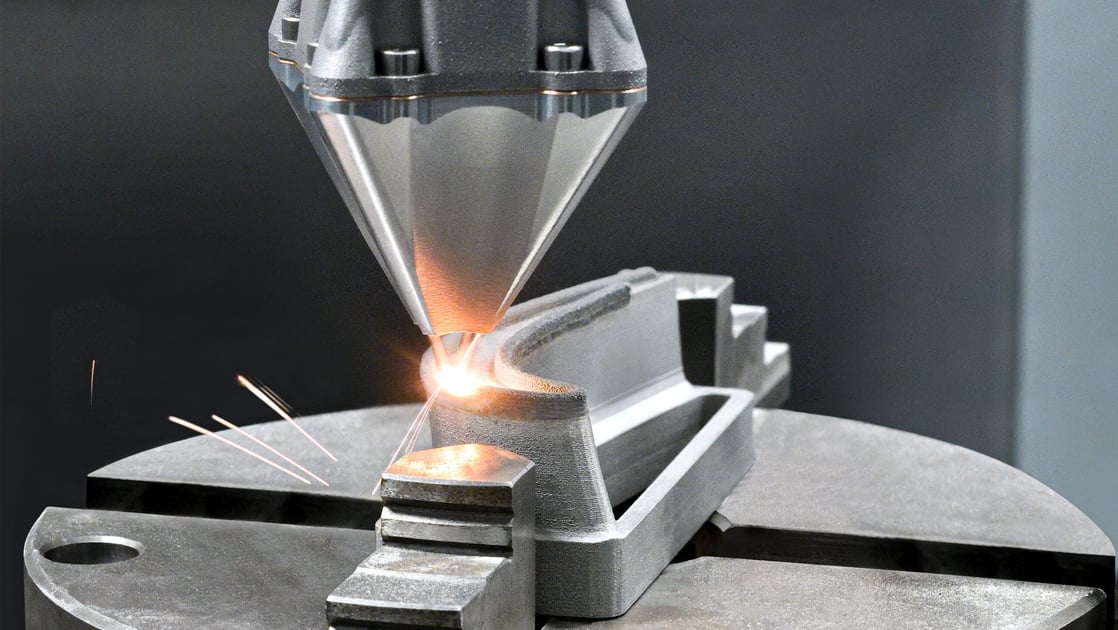

Directed Energy Deposition Ded Metal 3d Printing The Ultimate Guide Directed energy deposition (ded) is a more complex 3d printing process, typically used to repair or add additional material to existing components. it is completely possible to fabricate parts from scratch using this technology, but it is often used for industrial applications such as repairing turbine blades or propellers that have been damaged. Here is a complete guide to ded 3d printing technologies, the materials suitable for ded, different ded processes, ded and applications and where wire arc additive manufacturing fits into the picture.

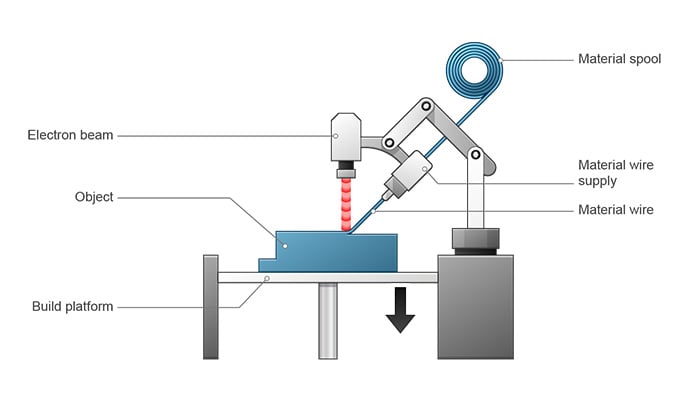

The Complete Guide To Directed Energy Deposition Ded In 3d Printing Would you like to make a deposit? this 3d printing process melts metal powder or wire as it's deposited to repair or manufacture a wide range of parts. The complete guide to directed energy deposition 3d printing directed energy deposition (ded) is one of the most significant advancements in metal additive manufacturing today. the technology uses energy sources like lasers, electron beams, or plasma arcs to melt metal powders or wires. Discover how directed energy deposition, also known as ded, lens, ebam, works and what are the usages of this fantastic technology. Direct energy deposition (ded) is a sequence of several similar metal 3d printing technologies that prints parts by melting and fusing material as it is deposited.

The Complete Guide To Directed Energy Deposition Ded In 3d Printing Discover how directed energy deposition, also known as ded, lens, ebam, works and what are the usages of this fantastic technology. Direct energy deposition (ded) is a sequence of several similar metal 3d printing technologies that prints parts by melting and fusing material as it is deposited. We have come up with this article to help you get what ded technology means, and also listed some of the most fascinating facts about it. Directed energy deposition (ded) is a system developed by optomec of new mexico to create, improve and repair metal parts. like sls, in ded, high power lasers build up 3d structures in layers, creating parts with high density and strength, ideal for mechanical applications. Whether you’re a seasoned engineer, a curious tech enthusiast, or someone diving into 3d printing for the first time, this article will walk you through every aspect of ded.

The Complete Guide To Directed Energy Deposition Ded In 3d Printing We have come up with this article to help you get what ded technology means, and also listed some of the most fascinating facts about it. Directed energy deposition (ded) is a system developed by optomec of new mexico to create, improve and repair metal parts. like sls, in ded, high power lasers build up 3d structures in layers, creating parts with high density and strength, ideal for mechanical applications. Whether you’re a seasoned engineer, a curious tech enthusiast, or someone diving into 3d printing for the first time, this article will walk you through every aspect of ded.

The Complete Guide To Directed Energy Deposition Ded In 3d Printing Whether you’re a seasoned engineer, a curious tech enthusiast, or someone diving into 3d printing for the first time, this article will walk you through every aspect of ded.

Comments are closed.