Understanding Cmms Software Features And Functions

Cmms Functions Overview Pdf These are the most unique and powerful features of cmms software, as identified through a survey of business owners, offering valuable insights into core cmms software requirements. Explore the core functionalities of cmms software and how it streamlines maintenance operations across various industries.

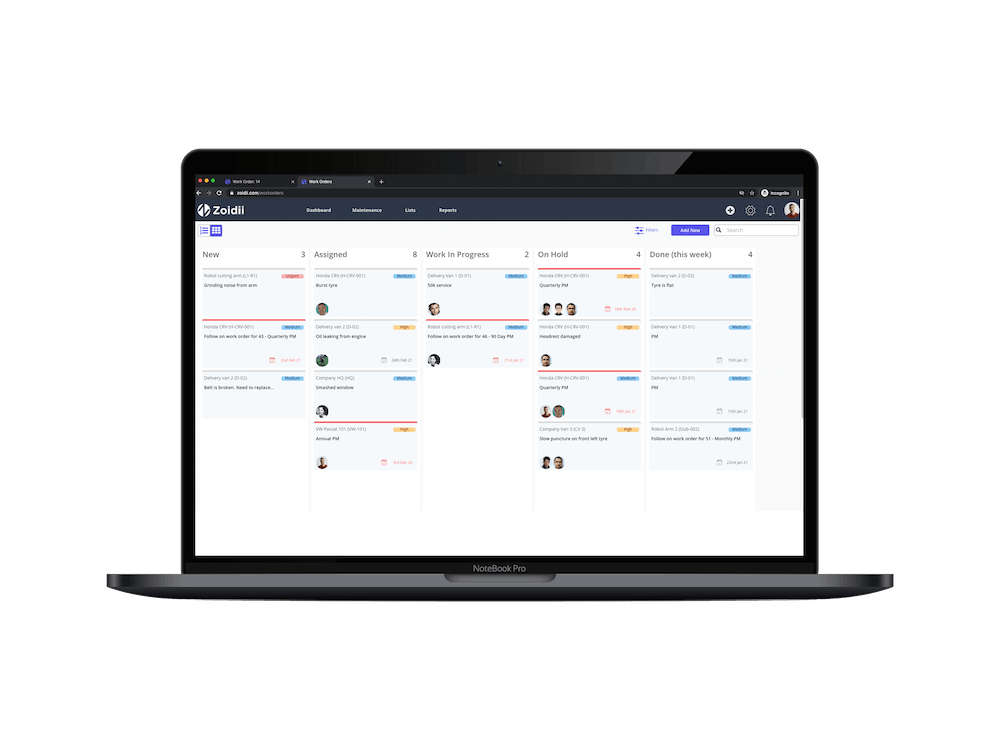

Why Use Cmms Software A detailed breakdown of the 9 essential features every modern cmms should have, covering asset management, preventive maintenance, work orders & more. Organizations use computerized maintenance management system (cmms) to manage their complex project operations effectively and efficiently. it helps in tracking all the work via live tracking, coordinates with equipment lifecycles, and manages stakeholder relationships to enhance communication. The cmms means computerized maintenance management system. cmms is software that helps organizations streamline maintenance tasks by managing work orders, scheduling preventive maintenance, tracking asset performance, and optimizing inventory. Cmms software ensures proactive maintenance through several key features, including mobile cmms access, which allows technicians to update work orders on the go, ensuring faster response times and seamless task completion.

What Is Cmms Software Pdf Business Computing The cmms means computerized maintenance management system. cmms is software that helps organizations streamline maintenance tasks by managing work orders, scheduling preventive maintenance, tracking asset performance, and optimizing inventory. Cmms software ensures proactive maintenance through several key features, including mobile cmms access, which allows technicians to update work orders on the go, ensuring faster response times and seamless task completion. Cmms platforms empower teams to plan preventive maintenance (pm) activities. by analyzing historical repair trends, manufacturer guidelines, and actual usage data, businesses schedule interventions before failures occur. Centralized maintenance management systems are software solutions designed to centralize the management of maintenance activities. they enable organizations to track work orders, schedule preventive maintenance, and manage inventory all from one interface. Modern cmms systems centralize asset information, automate maintenance tasks, provide insights into equipment performance, and optimize asset usage. they offer core features like work order and asset management, preventive maintenance, inventory management, and analytics. Cmms software performs a range of functions to enhance maintenance management. it acts as work order software, tracking maintenance orders and scheduling tasks, which is pivotal for maintenance teams in managing their workflows and reducing downtime.

Comments are closed.