Welding Standards Positions For Welding Pipe Aqc Inspection

Welding Standards Positions For Welding Pipe Aqc Inspection For welding pipe in shops, power plants, oil refineries, and chemical plants for crude oil, gasoline, and natural gas, the same basic welding positions described previously are used. Several standards are commonly used in welding to ensure the quality, safety, and reliability of welded structures across different industries. here are some of the key welding standards:.

Welding Standards Positions For Welding Pipe Aqc Inspection These standards are established by the american society of mechanical engineers (asme) and address materials, welding, inspection, and testing requirements to ensure piping systems perform safely under specified conditions. Effective quality planning relies on understanding code requirements, establishing clear inspection criteria, ensuring proper qualifications, planning for access, and maintaining timely communication between all parties. a site specific quality plan (ssqp) is critical to the project’s quality. Standards for welding positions: it is very important for the weld inspector to know the position, or location of a joint relative to the horizon, because it may determine what welding process, methods, and techniques can be used. For quality control (qc) engineers, understanding both the welding positions and processes is critical to maintaining quality, safety, and code compliance on every project.

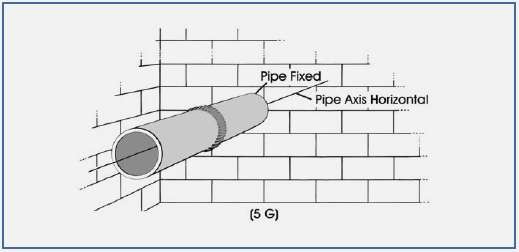

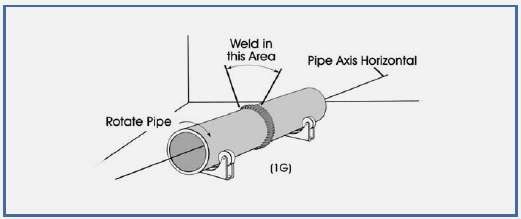

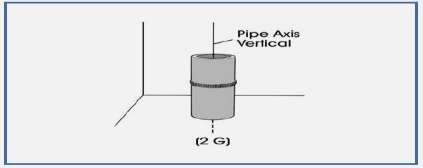

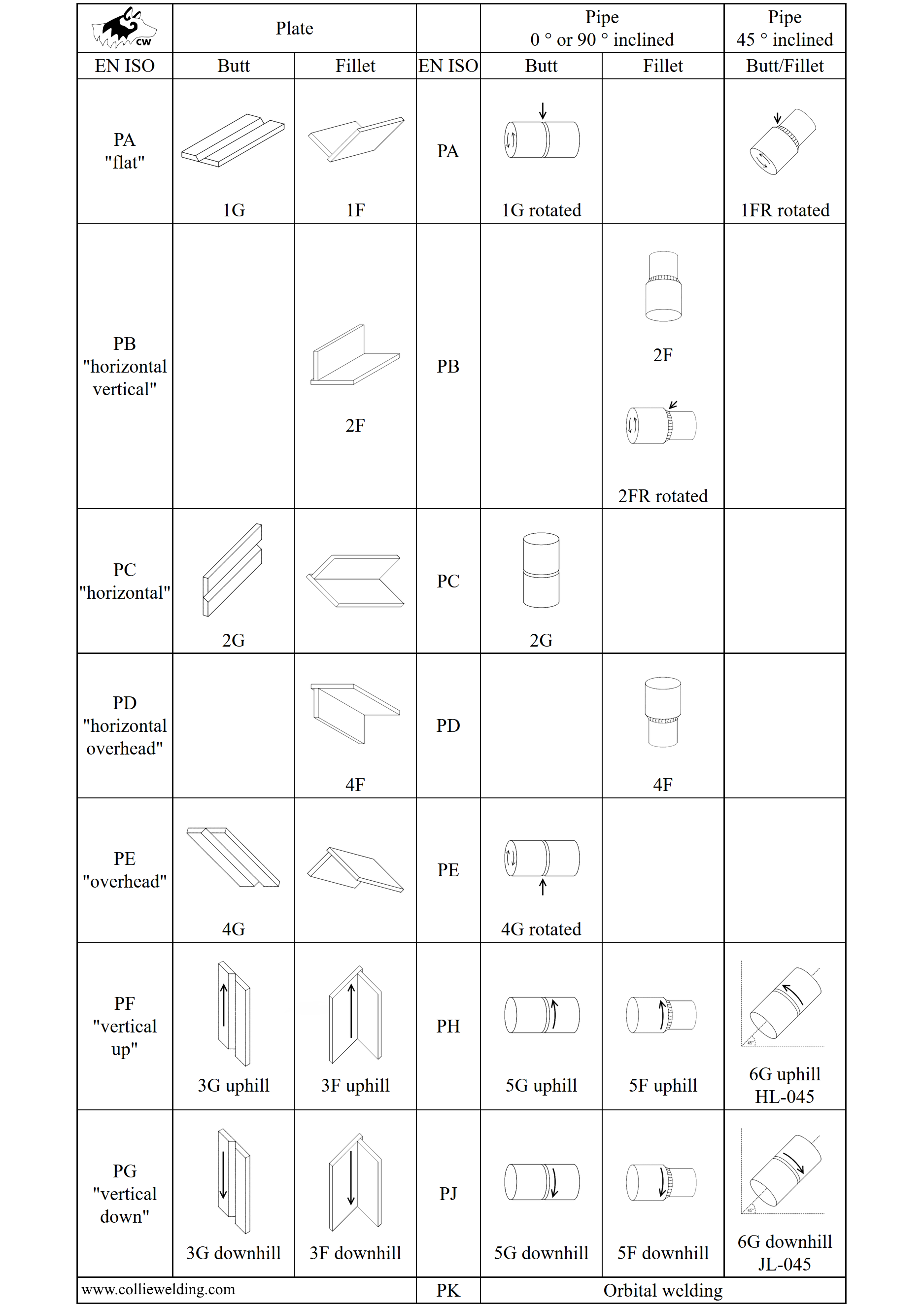

Welding Standards Positions For Welding Pipe Aqc Inspection Standards for welding positions: it is very important for the weld inspector to know the position, or location of a joint relative to the horizon, because it may determine what welding process, methods, and techniques can be used. For quality control (qc) engineers, understanding both the welding positions and processes is critical to maintaining quality, safety, and code compliance on every project. Understanding welding techniques, welding positions, welding consumables, weld preparation, and welding inspection documentation requirements. welds together metal components as specified by layouts, blueprints, diagrams, work orders, or oral instructions using mig or tig. Competency of welding organization to perform welding activities in accordance with codes, standards, and specifications specified. the roles and responsibilities of engineers, welding organizations, and welding inspectors are defined and appropriate for the work. Pipe welding positions refer to the various orientations in which a welder might work on a pipe. these positions are standardized to ensure consistency and quality across different projects and industries. Welding inspection and quality control are crucial in ensuring the safety and reliability of welded structures and equipment. in this article, we'll explore industry standards and best practices for welding inspection and quality control.

Welding Standards Positions For Welding Pipe Aqc Inspection Understanding welding techniques, welding positions, welding consumables, weld preparation, and welding inspection documentation requirements. welds together metal components as specified by layouts, blueprints, diagrams, work orders, or oral instructions using mig or tig. Competency of welding organization to perform welding activities in accordance with codes, standards, and specifications specified. the roles and responsibilities of engineers, welding organizations, and welding inspectors are defined and appropriate for the work. Pipe welding positions refer to the various orientations in which a welder might work on a pipe. these positions are standardized to ensure consistency and quality across different projects and industries. Welding inspection and quality control are crucial in ensuring the safety and reliability of welded structures and equipment. in this article, we'll explore industry standards and best practices for welding inspection and quality control.

Welding Standards Positions For Welding Pipe Aqc Inspection Pipe welding positions refer to the various orientations in which a welder might work on a pipe. these positions are standardized to ensure consistency and quality across different projects and industries. Welding inspection and quality control are crucial in ensuring the safety and reliability of welded structures and equipment. in this article, we'll explore industry standards and best practices for welding inspection and quality control.

Welding Positions

Comments are closed.